Gruppo Fabbri provides customized lines for the filling and packaging of lasagna, cannelloni and parmigiana in tray-sealing only, in modified atmosphere or in aluminum pans with preformed and crimped lid.

Filling and packaging lines for lasagna, cannelloni, parmigiana

These lines, branded CAVECO, are composed of:

To complete the packaging system, we are also able to supply the classic end-of-line components, such as weigh-pricing machines, labelling machines, etc.

The line can handle trays and trays in all the most up-to-date ecological packaging materials and can easily adapt to trays and trays of different shapes. The long feed section allows the installation of feeders dedicated to a single ingredient at a time.

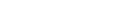

The line for the preparation and packaging of lasagna and cannelloni is characterized by extreme flexibility and can package the product with different ingredients, either in a pan or in a tray.

This type of line can process fresh, dry or frozen sheet of pasta in single or double way and generally performs the following operations in an automated manner:

– Tray unstacking on carousel or in line

– Loading of pasta sheet

– Béchamel and tomato dosage in two stages or mixed, depending on the customer’s recipe

– Grated cheese dosing

– Dosing of soft cheeses (such as mozzarella)

– Dosing of vegetables or condiments

– Forming cannelloni from fresh pasta sheets

– Continuous filling of cannelloni

– High precision cutting of cannelloni

– Packaging with closure from die-cut reel

– Packaging from preformed lid

– Packaging without production of scraps (very used in the catering industry)

The various dosers installed on the line are capable of handling solid foods (tomatoes, grated cheese) and liquids (sauces, béchamel) and are specially sized to avoid so-called “bottlenecks” when dosing a particular element.

Automatic systems are also used for loading the sheet of pasta or for forming cannelloni. The same line can also be converted to the use of aluminium trays with crimped lids, ideal for frozen lasagne or cannelloni to be placed directly in the oven. In this case, instead of a heat sealer we will find a preformed lid applicator and a seamer.

The advantage of an automatic line is that it makes it possible to optimize the number of dedicated operators, whereas a production line consisting of the heat sealer alone would necessarily use more people per shift to achieve the same productivity. To complete the offer, Gruppo Fabbri also provides barrier films for tray-sealing or MAP packaging, assistance during the installation phase, both ordinary and extraordinary maintenance service and spare parts.

by

by